- The Czochralski Crystal Growth process, also called as Cz growth is a method of crystal growth used to obtain single-crystal silicon ingots.

- Crystal Growth is the process where a pre-existing crystal becomes larger as more molecules or ions add in their positions in the crystal lattice.

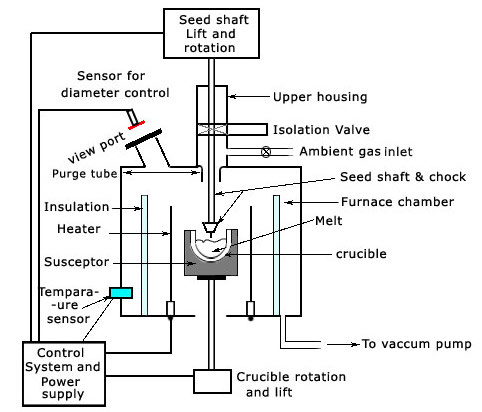

A Cz Growth system consists of four subsystems:

- Furnace – It contains quartz crucible, graphite susceptor, a heater, rotational mechanism, power supply and a chamber.

- Crystal Pulling Mechanism – It consists of seed shaft or chain, a rotation mechanism and seed chuck.

- Ambient control – It consists of a gas source, flow control, purge tube, and exhaust or vacuum system.

- Control system – This section usually consists of micro processing sensors and outputs for controlling the apparatus.

Furnace:

- The most important part of the furnace is the crucible. It is a cup in which contains the melt. Thus, it must be chemically un-reactive with molten silicon.

- It is usually made of quartz i.e. silicon dioxide also known as fused silica.

- Usually, this crucible can only be used once because, after the crystal growth, when the system is cooled down, due to the thermal mismatch, the quartz crucible usually cracks and gets broken. So we cannot reuse the crystal.

- The quartz crucible is placed inside a graphite susceptor which is used to support the crucible. Graphite is used as a susceptor since its melting point is very high.

- High purity graphite is used to prevent contamination of the crystal from impurities that would be volatilised from the graphite at the temperature involved.

- Heating is done by usually by RF (radio frequency) heating.

- The susceptor rests on a pedestal whose shaft is connected to a motor that provides rotation.

- Hottest parts of the apparatus are water cooled.

- Insulation is usually provided between the heater and the chamber wall.

Crystal Pulling Mechanism:

- It consists of a pull rod and at the end of the pull rod, a small seed crystal is fixed.

- The mechanism controls two parameters of growth process: pull rate and crystal rotation.

Ambient Control:

- The crystal growth must be conducted in an inert gas or vacuum. There must be no oxygen in the system because:

- The oxygen will form carbon dioxide with the graphite (carbon) and erosion occurs. Thus the erosion of graphite parts must be prevented.

- Secondly, oxygen should not react with molten silicon. If it reacts with silicon, it will form silicon dioxide and it is not desirable as we want high purity single crystal silicon.

- Therefore usually quartz chamber is first evacuated of all the gases present in the chamber and fill it up an inert gas like argon or helium.

Control system:

- It provides control of process parameters such as temperature, crystal diameter, pull rate and rotation speed using micro-processing sensors and outputs.

Working – Czochralski Crystal Growth process:

- In CZ technique, the electronic grade silicon (EGS) is placed in a quartz crucible for heating.

- Due to heating, the silicon gets molten. Thus, we have a melt inside the crucible.

- After the charge gets molten, it is uniformly in the liquid state, then a piece of highly pure and single-crystal silicon rod is inserted from the top of the crucible till it touches the silicon melt. This pure crystal silicon rod is called seed crystal.

- To ensure uniform heating of the melt, both the crucible and the seed rod are rotated in the opposite directions.

- Then, the seed rod is slowly pulled upwards. The melt that is in contact with the seed crystal gets solidified when it comes out of the silicon melt.

- The adhered silicon atoms orient themselves in the same fashion as the seed crystal. The crystalline silicon drawn out of the melt is called boule.

- The pull rate and thermal conditions must be carefully adjusted otherwise instead of solidification of melted silicon by seed crystal, the seed crystal itself gets melted which is not desirable.