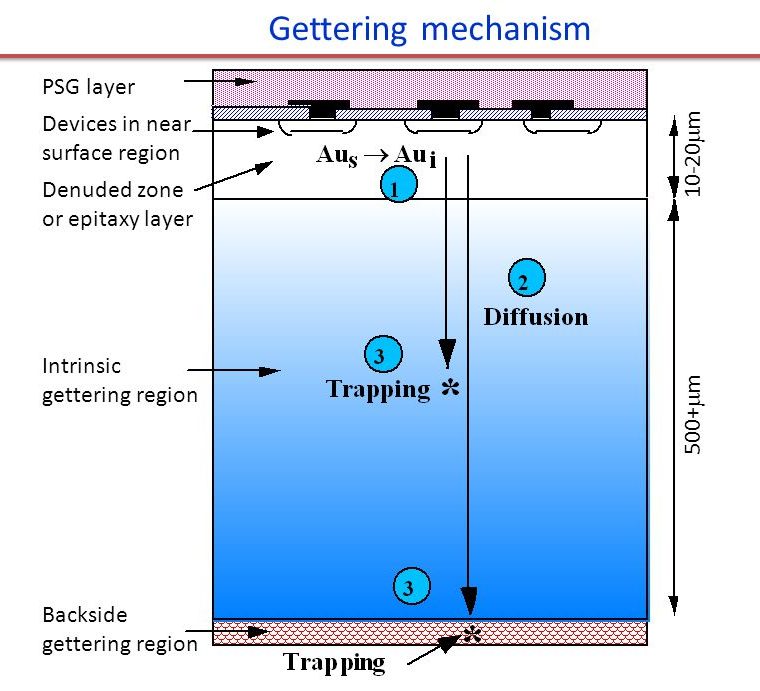

- Gettering is a process by which unwanted impurities are removed by providing them an alternate location where they prefer to reside.

- It is used to move contaminants or unwanted impurities into the bulk and away from the top surface i.e. the active regions of the device and traps them there.

- For integrated circuits, the primary unwanted species are metals.

- It usually consists of three steps:

- Making metals atoms mobile.

- Migration of these atoms to trapping sites.

- Trapping of these atoms.

Gettering can be extrinsic or intrinsic:

- Extrinsic Gettering: It refers to the gettering that uses external means to create the damage or stress in the silicon lattice in such a way that extended defects that are needed for trapping impurities are formed.These trapping sites or dislocations are usually located at the wafer backside.These dislocations will act as sinks for contamination.

- Intrinsic Gettering: It refers to the gettering that uses oxygen which is already present in the crystal.During crystal growth, a large concentration of oxygen is incorporated into the silicon boule. When the temperature is reduced, oxygen tends to precipitate.Oxygen precipitation has positive and negative aspects:(a) If there are oxygen precipitates in the active device regions, they can destroy the device.(b) But the oxygen precipitates that are present in the bulk provide sites for gettering of metals.Also the presence of oxygen (in the bulk and away from the active device regions) also makes silicon more robust which is particularly important for larger wafer sizes.

Since we are using the oxygen which is already present in the crystal, that’s why this process is known as intrinsic gettering.

So the goal is to remove the oxygen precipitates from the active device regions but keep them in the bulk for gettering of metals.

To remove the oxygen from near the surface (active device region), we can heat the wafer at around 1000 degree centigrade or above in inert ambient.

The oxygen from near the surface will be evaporated. So the active region is free of this oxygen precipitate, but it will still remain deeper in the bulk which can be used as gettering centres.