MOCVD (Metal Organic Chemical Vapor Deposition)

- Many materials have very low vapour pressure and thus are difficult to transport via gases. For these type of materials, MOCVD is used.

- In MOCVD, metal (for example Ga, Al, Cu, etc…) is chemically attached to an organic compound that has a very high vapour pressure.

- The organic-metal bond is very weak and can be broken via thermal means on the wafer, depositing the metal with the high vapour pressure organic being pumped away.

- An MOCVD system must be capable of the controlled growth of thin, atomically abrupt, extremely perfect epitaxial layers.

The growth system can be divided into three sub-components:

- Gas Delivery

- Reaction Chamber

- Gas Exhaust

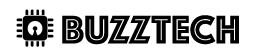

(1) Gas Delivery System:

- The gas chamber provides well mixed and well-controlled flow of a number of gases.

- For growing GaAs,

- H2, TMG (Trimethyl Gallium) or TEG, AsH3

- For p-type doping – DMZ (Dimethyl zinc)

- For n-type doping – SiH4

- For this process, we use OM (organometallic) arsenic source i.e. TBA (tertiary butyl arsine).

- The OM sources consist of a bubbler immersed in a controlled temperature bath of glycerin and water.

- OM vapour is obtained by heating the liquid in a constant temperature bath and bubbling H2 through the bath.

- The temperature of the bubbler must be carefully controlled since the vapour pressure depends exponentially on the temperature of the bath.

- The back pressure regulator is used along with the temperature of the bath to establish the mole fraction of the OM in the gas that is sent to the reactor.

- The OM source also includes valves so that the source can be isolated from the line and flushed with N2 when it is to be changed.

- The details of the gas delivery system depend on the particular OM being used.

- Some OM requires substantial heating in order to obtain a sufficient vapour pressure for deposition. For example TEAL (triethyl aluminium)

(2) Reaction Chamber:

- The vapour of MO formed are deposited on the wafer. The gas switching is used to avoid large gas transients.

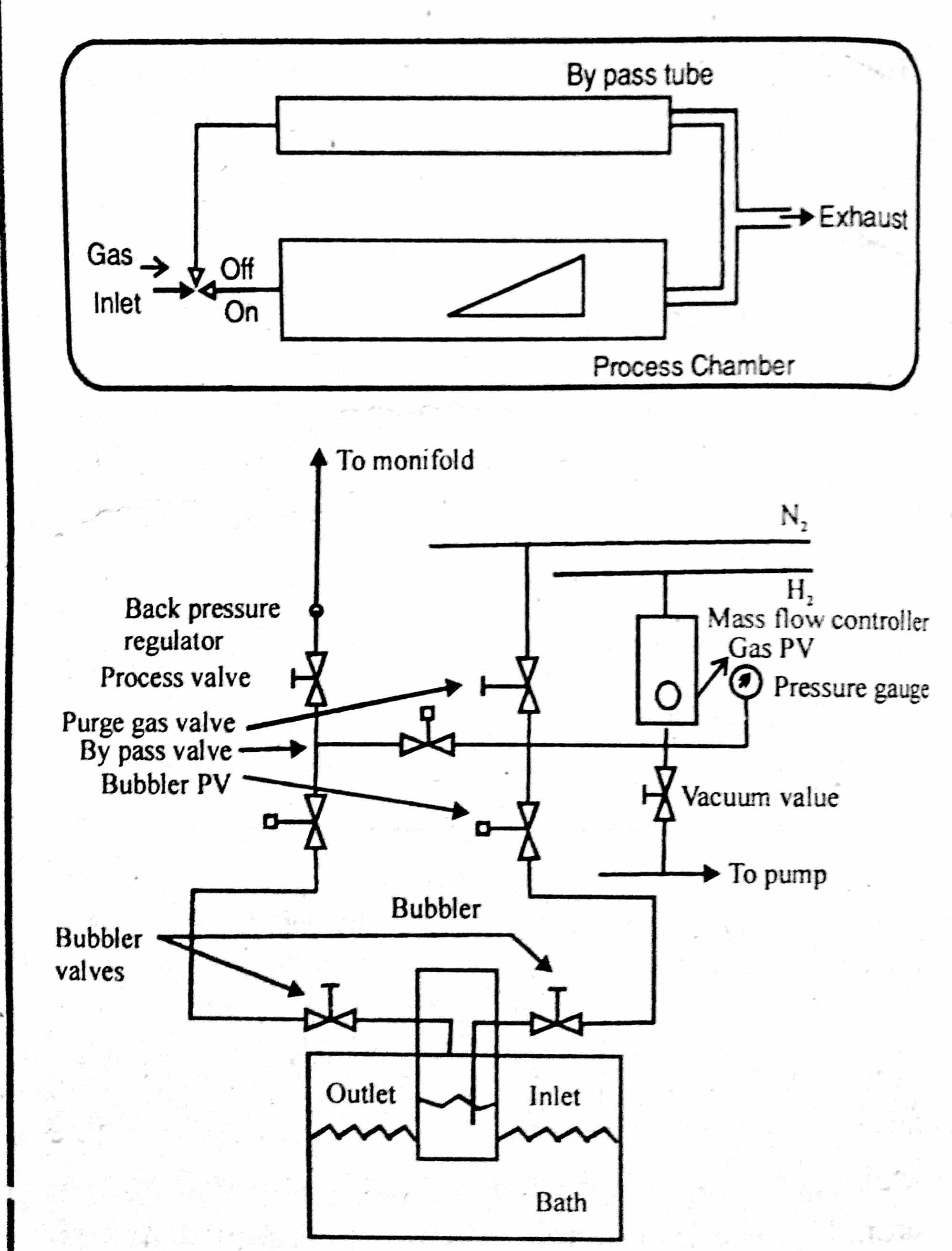

- Two common reactors are used:

- Wedge-shaped horizontal reactor

- Vertical impinging jet reactor or stagnation point flow reactor

- The gas enters the chamber in a fully developed flow. Gas velocity is zero at the walls and it increases periodically towards the centre of the inlet tube.

- In MOCVD process, the flow through the chamber must be laminar, with no turbulence or recirculation. Non-laminar and re-circulative flow trap gases in the chamber.

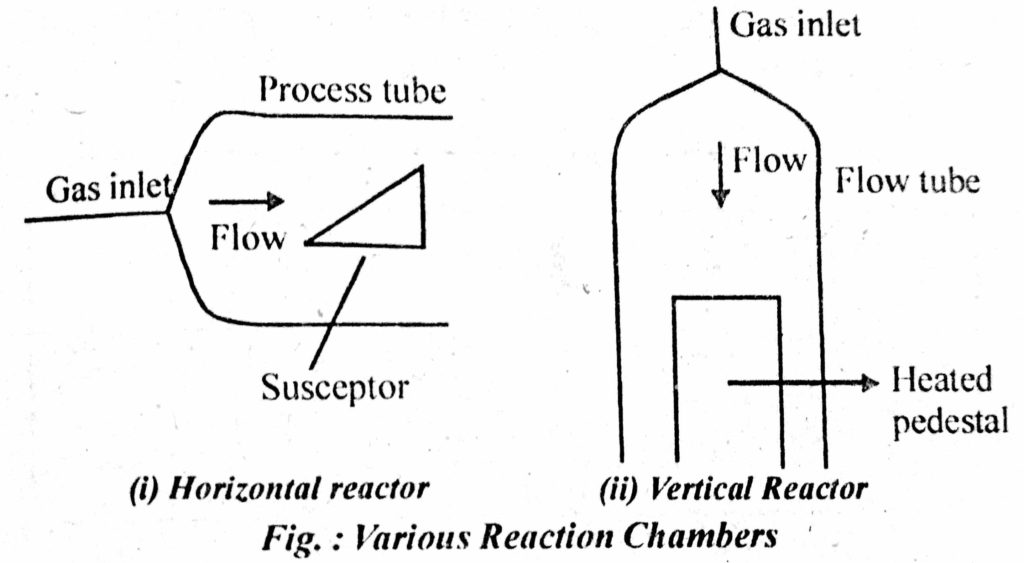

- The plot of growth of GaAs in MOCVD as a function of substrate temperature:

- At low temperature, the growth rate increases exponentially with temperature.

- At high temperature, the growth rate begins to drop, because H2 release and causes gallium to deposit on the walls of the chamber and deplete TMG source.

- Most GaAs growth is done in the intermediate temperature regime where the growth rate is determined by the arrival rate of the TMG.

(3) Gas Exhaust:

- It allows the system to operate at a controlled pressure.

- Growth at reduced pressure can improve uniformity and layer abruptness.

Problems in MOCVD system:

Carbon contamination and unintentional hydrogen incorporation are a major problem in MOCVD.

- This results in unintentional p-type doping. So for proper doping, the proper V/III ratio is chosen and the suitable amount of carbon gas is injected to remove out CH3 or C2H5 groups for removing contamination.

- Also, as the human body absorbs organic compounds very easily, the metal organics are very easily absorbed by humans. Once in the body, the weak metal-organic bond is easily broken, thus, poisoning the body with heavy metals that often cannot be easily removed by normal bodily functions.